“ONE STOP” Solution Provider

ALMUZAIN is one of the leading Industrial Services Companies caters to the ever-growing and complex demands of the Petrochemical & Refineries in Saudi Arabia. With a multinational team comprising professionals from 10+ countries, totaling over 1600+ highly trained and experienced individuals, the company possesses a substantial talent pool to draw from. ALMUZAIN is approved vendor of SABIC, ARAMCO, SASREF, SAMREF, YASREF, SATORP, SADARA, SIPCHEM, FARABI, TASNEE, ADVANCED, NATPET, DUGAS (Dubai) to name a few.

Read more

Let’s check how we

optimize your industry.

Explore the core functionality

of the Almuzain

News & Events

Double Recognition from IBNZAHR for MTBE-1 & Utility-1 Turnaround – 14th March 2024

Almuzain's unwavering commitment to Safety, Quality, and Excellence earns double recognition.....

View more

ADVANCED Recognizes Almuzain for Outstanding Performance for “Cold Box Revamp Project” during TAM 2024 – 24th February 2024

Almuzain is proud to announce the receipt of Certificate of Appreciation from ADVANCED.....

View more

Almuzain Recognized by PETROKEMYA for Successful Completion of Y’2024 OLEFINS-II & UTILITY T/A – January 2024

Almuzain is proud to announce the receipt of Certificate of Recognition from PETROKEMYA for its outstanding contributions to.....

View more

Almuzain Celebrates Saudi Founding Day!

Almuzain celebrated Saudi Founding Day with cultural activities, traditional fare, and national pride.....

View more

Almuzain receives Certificate of Appreciation from SATORP for Train-I Turnaround,2023 on 20th December 2023

Almuzain is proud to announce receipt of Certificate of Appreciation from SATORP....

View more

Almuzain Receives Certificate of Recognition from SADARA for Hydrocarbon Turnaround 2023

Almuzain is proud to announce receipt of Certificate of Recognition from SADARA...

View more

Almuzain Recognized by SAMREF for Successful Participation in Buddy Manager Program – November 2023

Almuzain is proud to announce receipt of a Certificate of Appreciation from SAMREF...

View more

Almuzain Receives Prestigious “S-Chem Contractor Safety Excellence Award 2022” – 12th December 2023

Almuzain is proud to announce receipt of the S-Chem Contractor Safety Excellence..

View more

Almuzain Recognized as Best PH-II Main Contractor by PETRORABIGH

We are thrilled to announce that Almuzain has been recognized for its exceptional performance on the PETRORABIGH..

View more

Almuzain Receives Appreciation Letter from YASREF – 5th July 2023

Almuzain is proud to announce receipt of an appreciation letter from YASREF...

View more

MA’ADEN Recognizes Almuzain for Outstanding Turnaround Performance

Almuzain is proud to announce the receipt of Certificate of Appreciation from MAADEN...

View more

IBN ZAHR Recognizes Almuzain for Safe and Successful Turnaround Performance – May 2022

Almuzain is proud to announce its recognition from IBN ZAHR with a precious Memento in...

View more

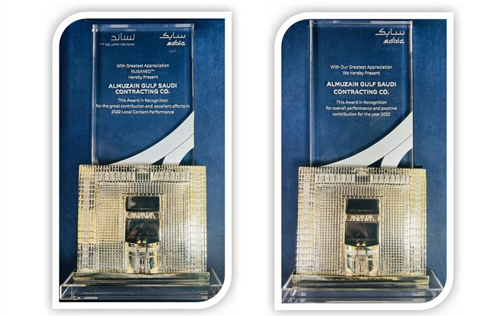

Almuzain Celebrates Two Prestigious Awards from SABIC – 20th March 2023

We are thrilled to announce that Almuzain has been recognized by SABIC with two prestigious awards for...

View more

ALMUZAIN Receives Prestigious Award from SABIC - January 19th, 2023

We are thrilled to announce that Almuzain have been recognized by SABIC...

View more

Almuzain Recognized for Successful Bottom Plate Replacement at SIPCHEM – February 21st, 2023

We are proud to announce that Almuzain has received a certificate of appreciation from SIPCHEM ...

View more

Almuzain Recognized by Saudi Aramco for Catalyst Loading Activities at Ras Tanura Clean Fuel Project

Almuzain is proud to announce receipt of Certificate of Appreciation from Saudi Aramco's RTR ...

View more

Almuzain Recognized by IBN ZAHR with Certificate of Appreciation for Turnaround Mar-Apr 2022

Almuzain is proud to announce receipt of Certificate of Appreciation from IBN ZAHR...

View more

Almuzain Recognized by Solvay for Successful Completion of SADARA SRU Project

Almuzain is proud to announce the receipt of Certificate of Recognition from Solvay...

View more

Almuzain Celebrates Recognition from SADARA for Chemical Turnaround 2022

Almuzain is proud to announce receipt of Certificate of Recognition and Memento...

View more

Almuzain Receives Prestigious DUGAS Certificate of Recognition for Best EHS Work Practices – 28th March 2022

Almuzain is honored to announce its receipt of Certificate of Recognition from...

View more

RAMCON 4th Reliability & Maintainability Conference and Exhibition 2023 held at Grand Hyatt Al Khobar, KSA from 26th – 28th November, 2023.

The RAMCon23 was a resounding success...

View more

English Language Improvement Course Certificate distribution ceremony for the 1st Batch Saudi National’s at WCC Academy.

We are delighted to share the proud and joyous moments....

View more

SToTme 2023 Wraps up a Successful 4th Annual Shutdowns, Turnarounds, and Outages Technical Conference & Exhibition

Al-Khobar, KSA - The 4th Annual Shutdowns, Turnarounds, and Outages Technical Conference...

View more

SABIC Supplier Recognition Award 2023.

ALMUZAIN is one of the leading Industrial Services Companies, has been recognized for their outstanding contributions and efforts by SABIC. The company recently awarded Almuzain...

View more

Almuzain Gulf Saudi Contracting Co. featured in the January 2023

Almuzain Gulf Saudi Contracting Co. featured in the January 2023 - 68th edition of Al-Senaat Al-Watania Magazine, a highly esteemed publication...

View more

SAMREF Recognition Award 2018.

Almuzain's Scaffolding Division, a leading provider of scaffolding services in Saudi Arabia, has been awarded a Certificate of Appreciation by Saudi Aramco Mobil Refinery Co. Ltd (SAMREF)...

View more

Almuzain, on the IBB TIA project in March and April of 2014

Almuzain, working on the IBB TIA project in March & April of 2014, has been recognized by SAFCO for their exceptional commitment to safety...

View more Trusted partner to leading Oil,

Gas and Petrochemical Industries.

EVERGROWING fleet in AL-Jubail

“Your Trusted Source for Rental Solutions and Seamless Operations”

ALMUZAIN's equipment rentals is commitment to provide comprehensive solutions to their clients. With a wide range of equipment available for rent, ALMUZAIN is able to provide clients with the flexibility and versatility they need to carry out their operations effectively and efficiently. This includes equipment such as cranes, forklifts, welding machines, generators, compressors, and more. By providing these services in-house, ALMUZAIN is able to reduce the need for multiple contractors and improving overall project efficiency.

Read more

-

20

Years ofexcellence

-

1600

Skilled & knowledgablemanpower

-

15

Different services

-

40

Valuable clients

WORKING TOGETHER ASTRUSTED PARTNER

Turnarounds are critical events that involve shutting down a facility for maintenance or upgrades, which can have significant financial implications for the organization. Our successful completion of complex turnarounds in the petrochemical and refineries industry over the last decade is a significant achievement. Working as trusted partner to ensure we deliver maximum value to all stakeholders. Combining our experience with the best safety, quality and on time record we have been the trusted partner to all our clients.

Zero harm in projects

Zero Harm in projects is a concept that aims to ensure that all people involved in a project, including workers, contractors, and members of the public, are kept safe and free from harm.

Higher Productivity

Improves efficiency, reduce waste, and achieve goals more effectively. By identifying areas of inefficiency and implementing targeted solutions, businesses can improve their bottom line and stay competitive in an increasingly challenging marketplace.

Innovation and creativity

Complex problems often require novel solutions that push the boundaries of existing knowledge and practices. Innovation and creativity involve generating new ideas and approaches that challenge conventional thinking and lead to breakthrough solutions.

Health, Safety & Environmental Policy

ALMUZAIN's commitment to a 'Zero Harm, Zero Accidents' policy is an important demonstration of its commitment to safety in all its operations. This policy represents a goal of achieving a workplace that is free from harm or accidents, and it signals a strong commitment to the health and safety of all stakeholders, including employees, customers, suppliers, and the wider community.

View HSE policy