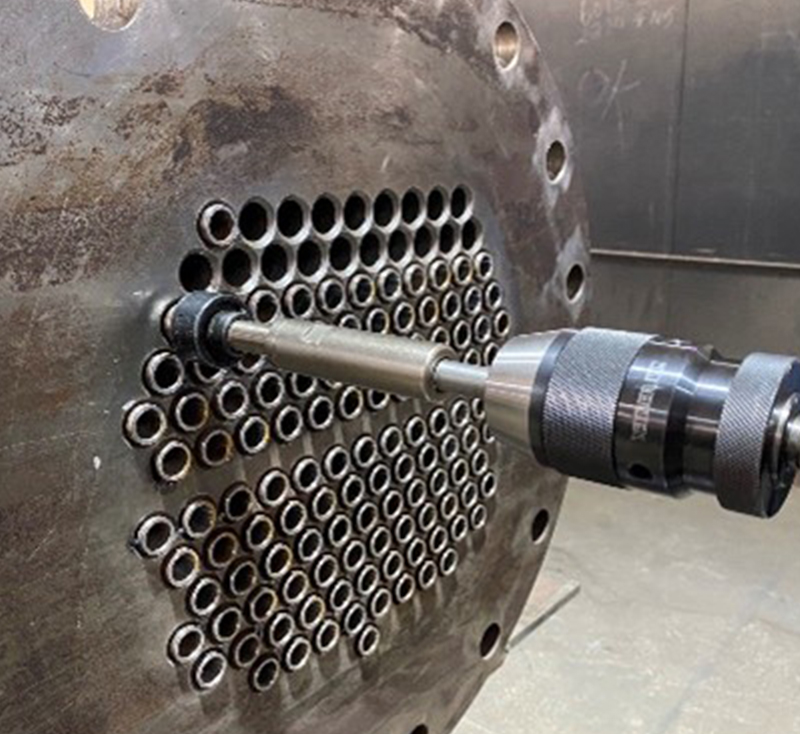

Internal Tube Cutting

Internal tube cutting is a process used to remove a portion of a heat exchanger tube that cannot be plugged through external means, such as puncturing or mechanical fit plugs. This process is typically necessary in cases where the leak is located at the tube sheet joint or where there is a high pressure difference. ALMUZAIN have specially designed tools to cut and remove tubes up to 2.Internal tube cutting is a complex process that requires specialized equipment and experienced technicians.

General overview of the internal tube cutting process:

- Inspection and Preparation: The heat exchanger is inspected to identify the location and extent of the damage or corrosion in the tubes. The exchanger is then cleaned and prepped for the internal tube cutting process.

- Tube Cutting: A specially designed cutting tool is inserted into the tube and used to cut it into two sections. The cut is typically made close to the tube sheet to allow for easy removal of the stubs.

- Tube Removal: The cut tube sections, or stubs, are removed from the heat exchanger using a tube puller or similar equipment.

- Tube Sheet Cleaning and Repair: The tube sheets are inspected and cleaned to ensure they are free of debris and any damage is identified and repaired as necessary.

- New Tube Installation: New tubes are then installed in the heat exchanger, typically using a tube expander to ensure a secure fit between the tubes and the tube sheets.

- Final Inspection: The heat exchanger is then inspected again to ensure that the new tubes are properly installed and free of any damage or defects. The exchanger is then reassembled and tested before being put back into service.

Trusted partner to leading Oil,

Gas and Petrochemical Industries.

LEADING INDUSTRIAL SERVICE PROVIDER

IN THE KINGDOM OF SAUDI ARABIA

Partners