Re-Grooving Tube Hole in Tube Sheet

Re-grooving tube holes in a tube sheet is a process used to repair damaged or worn tube holes in a heat exchanger tube sheet. Over time, the tube holes in the tube sheet can become damaged or worn due to the constant expansion and contraction of the tubes. Re-grooving involves cutting new grooves or channels in the tube sheet to accommodate new tubes. Re-grooving tube holes in a tube sheet is a complex process that requires specialized equipment and experienced technicians.

General overview of the re-grooving process:

- Inspection: The tube sheet is inspected to identify any damaged or worn tube holes that need to be re-grooved.

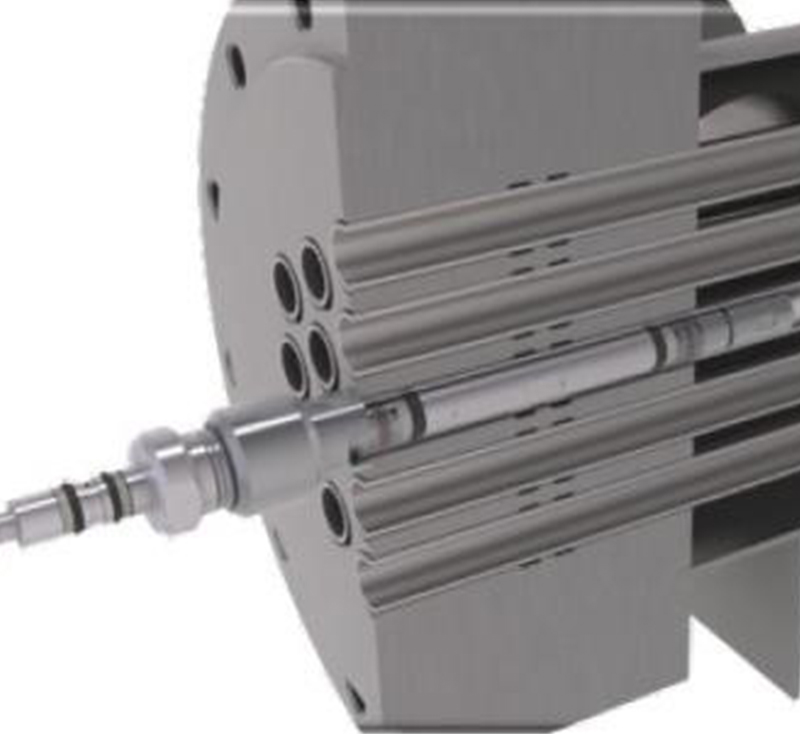

- Grooving: The damaged or worn tube holes are re-grooved using specialized equipment, such as a tube sheet grooving machine. The grooves are cut to the correct depth and spacing to accommodate the new tubes.

- Tube Installation: The new tubes are then installed into the re-grooved tube holes, typically using a tube expander to ensure a secure fit between the tubes and the tube sheet.

- Testing: The heat exchanger is then tested to ensure that the new tubes are properly installed and there are no leaks or other issues.

Trusted partner to leading Oil,

Gas and Petrochemical Industries.

LEADING INDUSTRIAL SERVICE PROVIDER

IN THE KINGDOM OF SAUDI ARABIA

Partners